Is our working environment safe?

As per the International Labour Organization, every 15 seconds, a worker dies from a work-related accident or disease. Every 15 seconds, 153 workers have a work-related accident. Every day, 6,300 people die as a result of occupational accidents or work-related diseases – more than 2.3 million deaths per year. 317 million accidents occur on the job annually; many of these resulting in extended absences from work. The human cost of this daily adversity is vast and the economic burden of poor occupational safety and health practices is estimated at 4 per cent of global Gross Domestic Product each year.

The indirect costs of accidents are usually greater than the direct costs. A conservative estimate of losses for every $1 of direct accident costs, there is $3 of indirect costs. Some studies indicate the hidden costs can be 4 to 10 times the insured costs. Indirect costs to consider include :

- Time lost from work by injured employee

- Lost time by fellow employees

- Damage to tools, equipment, and other property

- Loss of production / Loss of business opportunity

- Spoilage – fire, water, chemical, debris, etc

- Administrative and legal costs

- Changes to insurance premium / loan settlement terms

- Loss of company image

Just as there are many hidden costs due to accidents, there are hidden savings in accident prevention. For this reason, the phrase “loss control” is often used in safety management. Every accident you prevent save direct and indirect accident costs – affecting your bottom line. Other benefits of accident prevention efforts include:

- Safe / uninjured employees

- Minimum damage / Loss to properties and material

- Production supervisors/managers can focus

- efforts on other projects

- Increased employee security at work

Who can provide assistance?

Global Institute of Safety, Security and Technology is an organization with local and foreign professionals who has over 15 years of local and international experience in Sri Lanka, Singapore, USA, Malaysia, India, Gabon and Nigeria.

All our Training modules are fully compatible with IOSH / British Safety Council (UK) and International and O&G industry specifications / requirement.

- HSE / OSH management system and HSE case

- Hazard effect management process

- Risk Assessment and Risk Control

- Minimum health maintenance standards

- Emergency response procedures and plans

- Accident Investigation and Root Cause Analysis

- Focused HSE training for critical HSE / OSH positions

- Journey and Fleet management

- Hazardous material handling

- Fleet / equipment pre-mobilization inspection, verification and periodic inspection

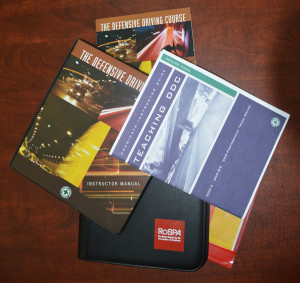

- Defensive Driving for commercial drivers, executives and individuals (meeting RoSPA-UK or NSC-USA standards)

- “Hearts and Minds” – Mind set change for Proactive OSH / HSE culture

- Critical competency development planning

- Resource optimization, Lean production and Six Sigma

We are using genuine world class training materials to provide all the service

|

|

|

|

|---|

Contact us for further details

HSE Training HSE and Technical Consultation

Affiliation and Accreditation